In manufacturing, every maintenance decision ties back to one thing: uptime. When a spindle goes down, production slows, schedules slip, and costs climb fast. That’s why a rebuild can’t be based on assumptions or guesswork.

If a spindle can’t be properly tested before it leaves the repair facility, you’re not getting a rebuild — you’re getting a gamble.

For maintenance managers who are responsible for performance, budgets, and accountability, testing isn’t a “nice to have.” It’s the difference between confidence and risk.

That’s where Motor City Spindle Repair takes a different approach: if we can’t test it, we won’t rebuild it.

The Risk of Rebuilding Without Testing

Without testing, you don’t truly know:

-

If vibration levels are acceptable

-

If balancing is correct at operating RPM

-

If temperatures will remain stable

-

If runout meets precision requirements

-

If the spindle will survive real production conditions

When that untested unit goes back into the machine, your shop becomes the test stand. And that’s expensive.

Unexpected noise, poor finishes, premature bearing failure, or another crash can put you right back where you started — only now you’ve lost even more time.

Why Testing Matters to Maintenance Managers

As a maintenance leader, you’re judged on reliability. Your job isn’t just to “fix things.” It’s to prevent repeat failures and protect production capacity.

Testing gives you proof.

It confirms that the spindle is not only assembled correctly, but actually capable of performing at the speeds and loads your machines demand. It provides measurable data — vibration readings, temperature trends, balance results, and runout verification — instead of hope.

When you reinstall a tested spindle, you can do it with confidence, not crossed fingers.

That peace of mind matters when your line is running 24/7 and downtime costs thousands per hour.

What Real Spindle Testing Looks Like

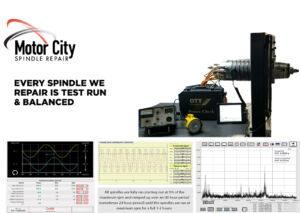

A properly rebuilt spindle should be run on a dedicated test stand that simulates real operating conditions. The unit is gradually brought up to speed, monitored closely, and evaluated using precision instruments.

During this process, technicians verify balance, check vibration signatures, monitor bearing temperatures, and confirm the spindle performs smoothly across its full RPM range.

If something is off — even slightly — it’s corrected before the spindle ever reaches your floor.

Because once it’s installed, it should simply work.

The Hidden Cost of Skipping This Step

Skipping testing might save a repair house a few hours. But it can cost a manufacturer days.

One failed reinstall can mean:

Lost production

Overtime labor

Missed deliveries

Frustrated operators

And another emergency teardown

For maintenance teams already stretched thin, repeating the same repair twice isn’t just costly — it’s exhausting.

Testing eliminates that cycle. It catches problems early, when they’re still cheap and easy to fix.

Why Motor City Takes Testing Seriously

Every qualifying spindle is run on dedicated test stands and validated with vibration analysis, temperature monitoring, and dynamic balancing. Units are proven at speed before they ever leave the building. If a spindle can’t be properly tested to verify performance, it doesn’t ship.

That philosophy protects your shop.

It means you’re not just getting new bearings and fresh grease. You’re getting documented performance and a spindle that’s ready for real production.

For maintenance managers, that translates into fewer callbacks, fewer surprises, and fewer late-night emergencies.

A Partner You Can Trust, Not Just a Repair Vendor

The best repair providers don’t just fix equipment. They help you reduce risk.

When you work with a team that prioritizes testing, you gain more than a rebuilt spindle. You gain confidence that the job was done right the first time.

You gain data to support your decisions.

You gain reliability for your machines.

And you gain a partner who understands that uptime is everything.

Don’t Settle for “Rebuilt.” Demand “Proven.”

Before sending your next spindle out, ask one simple question:

How is this unit tested before it comes back to me?

If the answer is unclear, that’s a red flag.

Because if it can’t be tested, it shouldn’t be rebuilt.

If you want repairs you can trust — validated, documented, and ready for production — Motor City is ready to help. Reach out for a free quote or to discuss your current spindle challenges. Your uptime deserves proof, not promises.

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE