The True Cost of Spindle Failure: Why Proactive Repair Saves More Than It Costs

Spindle Failure Is a Production Problem

For maintenance managers, spindle failure isn’t just a repair issue. It impacts production schedules, delivery dates, budgets, and team stress. When a spindle goes down, everything slows down. The real cost isn’t the repair invoice, it’s the downtime that follows.

Downtime Is Where the Money Is Lost

Every hour a machine is idle means lost revenue. Emergency repairs force rushed decisions and limit your options. Instead of choosing the best solution, you’re often choosing the fastest one, which usually costs more long-term.

Proactive Repair Keeps You in Control

Proactive spindle repair puts the power back in your hands. Testing, monitoring, and planned service allow maintenance to be scheduled instead of forced. You control downtime, protect production, and stabilize budgets.

Spindles Always Give Warning Signs

Most spindles don’t fail without warning. Increased vibration, unusual noise, heat, poor surface finish, and shortened tool life are signals. Catching these early prevents catastrophic failures and secondary damage to tooling and machine components.

Testing Turns a Repair Into a Solution

A Healthy Spindle Protects the Whole Machine

Failing spindles don’t just damage themselves. They affect tooling, tapers, surface finish, scrap rates, and overall machine accuracy. Proactive repair protects the entire machining system.

Backup Options Reduce Risk

Spindle exchange programs and backup spindles turn shutdowns into simple swaps. Instead of stopping production, you keep running while repairs happen in the background.

Why Motor City Spindle & Ball Screw

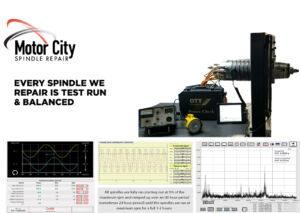

FREE TESTING AND BALANCING

FREE 1 YEAR CERTIFIED WARRANTY

At Motor City Spindle & Ball Screw, we’re more than a repair house, we’re a trusted reliability partner. Our job is to help keep your operation running. Every spindle is repaired, tested, and verified with your uptime in mind.

We don’t guess. We measure. We don’t rush. We validate. Our testing process ensures every spindle leaves our shop balanced, stable, and ready for production. That consistency is why customers trust us with critical equipment.

We also help you plan instead of panic. Through testing, vibration analysis, exchange programs, and preventive strategies, we give maintenance teams control over their maintenance schedules and confidence in their equipment.

When you work with a trusted repair house, you gain more than a repaired spindle. You gain reliability, predictability, and peace of mind. And in manufacturing, that’s what keeps production moving.

sales@motorcityrepair.com

CONTACT US ANYTIME IF YOU would LIKE TO CHAT WITH OUR EXPERTS OR STOP BY OUR 25,000 SF MANUFACTURING FACILITY LOCATED IN DEARBORN, MICHIGAN!

(734) 261-8600 OR EMAIL US AT SALES@MOTORCITYREPAIR.COM

Need a FREE ESTIMATE? Click HERE To view our most recent blog post, click HERE